Description

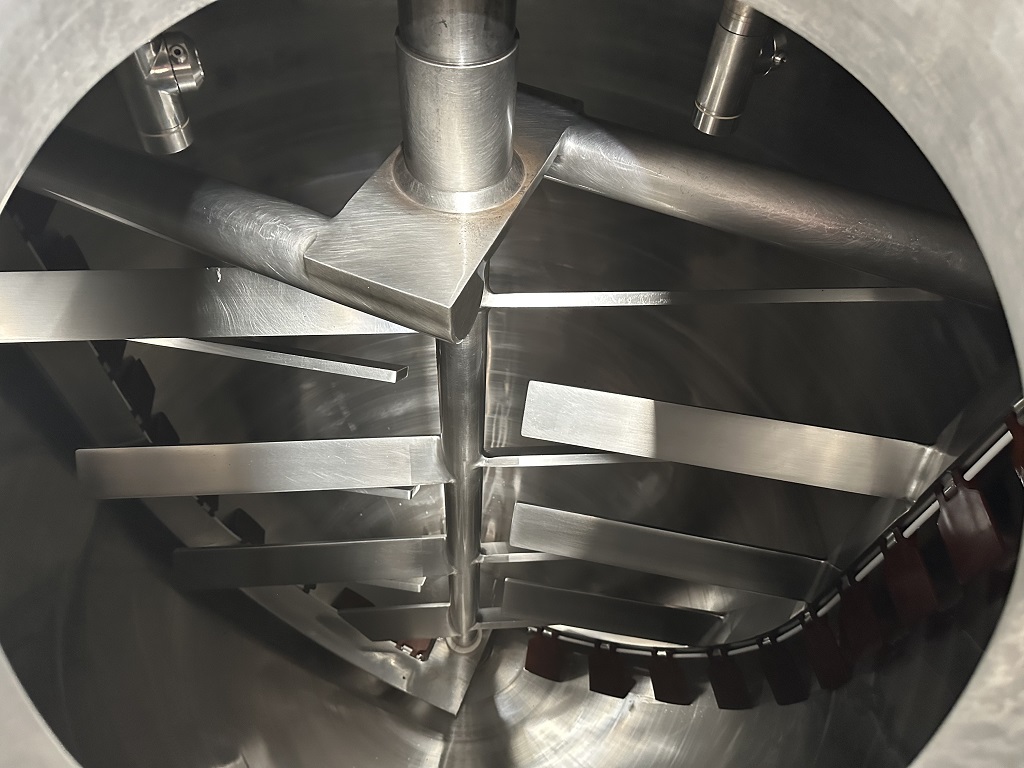

USED 2014 LEE 400 Gallon Dual Motion 316L Stainless Jacketed Kettle, Process Mix Tank, Model #400D9MS, Serial #82182-1, NB #12845, Year: 2014, Last Used In Food Production, Stainless construction, 52” diameter x 60” sidewall, Side and Bottom Jacketed, MAWP 100 PSI @ 338 Degrees F, Internal MAWP 50 PSI @ 300 Degrees F, Dome Top, Hemispherical Bottom with 2″ Center Discharge, Top Manway Entrance, Dual Motion With Side and Bottom scrape, 7.5 HP Top Agitator Mixer, Electrical 230/460 Volt / 50/60 HZ. / 3 Phase, Stainless bridge mount, Flush RTD Sensor Port, 17” Stainless Legs, Multiple Top Inlets, Overall Dimensions 56” Wide x 84″ Long x x 125” High. This tank was professionally removed from a major food production facility. This LEE Industries 400 Gallon Process Tank, kettle may be inspected at our Used Packaging Equipment LLC Caddo Mills, TX. 75135 Warehouse Facilities. Please reach out and call us today to discuss your packaging and processing equipment needs.