Description

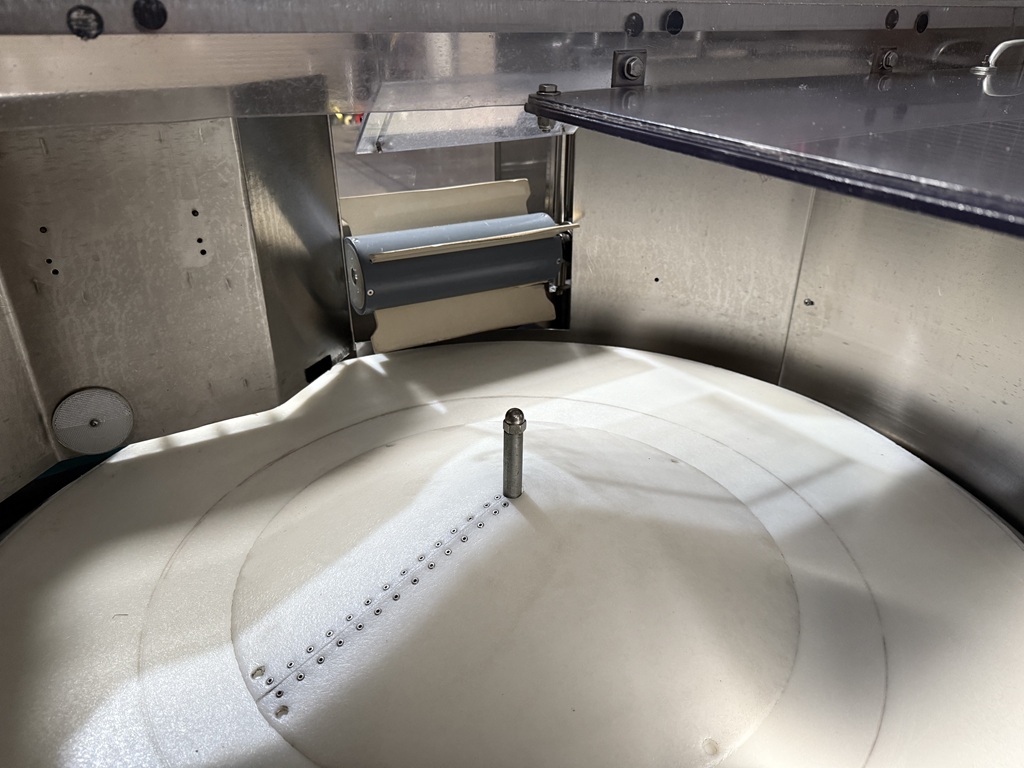

USED Pace M400 Empty Bottle Unscrambler with Bottle Feed Elevator Hopper, Model #M400, Serial #1165, Includes 50 cu. ft. Stainless Empty Bottle Hopper Feeder Elevator, Capable Of Speeds Up To 350 bpm; Based Upon Product Specifications, Hook Bottle Standup Feature, Last Running 10 oz Round Bottle, 48” dia. Rotary Sorter Feed Bowl, Capable of handling rounds, cylinders, jars, ovals, squares, rectangles, and other shaped bottles, Variable Speed Controls, Flapper Wheel Assembly, Photo Eye Product Detection, Inline System, Stainless Construction, Stainless Electrical Panel, Stainless Floor Levelers, Electrical Disconnect, Operator Interface Controls. This unit is very well constructed and has been professionally removed from a mid-size bottling plant. The bottle unscrambler has been function tested at our facility and is immediately available to ship. The equipment is currently located at our Used Packaging Equipment LLC Warehouse Facilities located in Caddo Mills, TX. 75135. Please reach out to us today to discuss all of your used packaging machinery needs.