Description

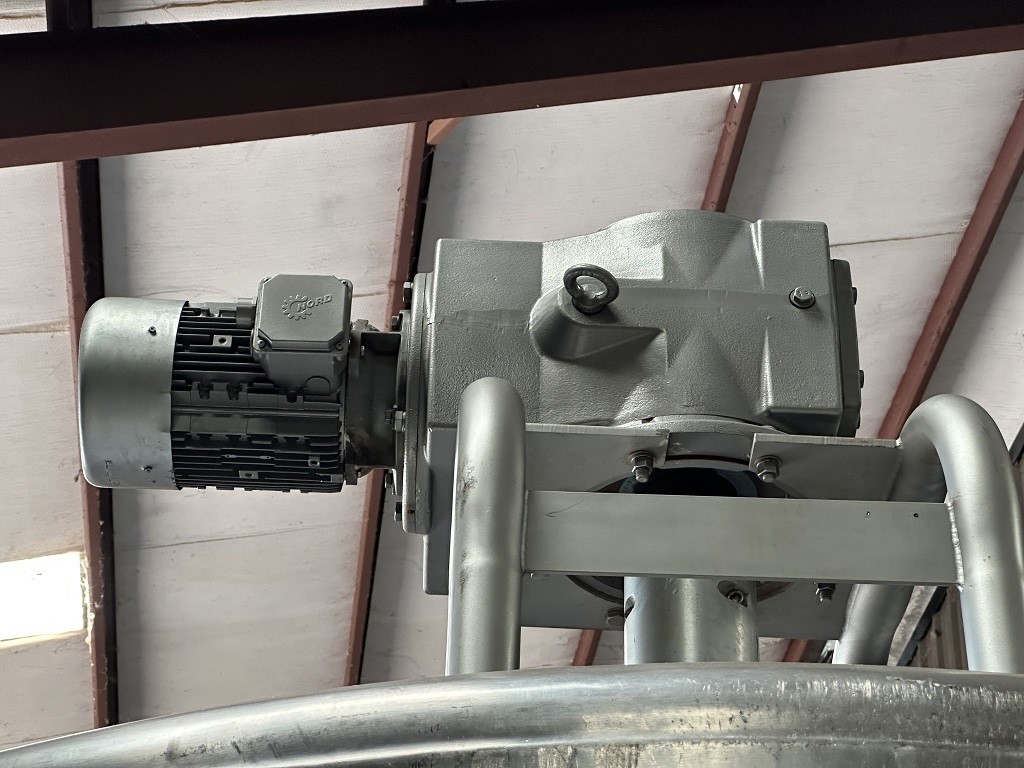

USED DCI 2,000 Gallon 316L Stainless Insulated Process Mix Tank, Serial #94-F-18596-A, MFG by DCI in ST. Cloud, MN, 96″ Diameter x 92″ Side Wall, 316L Stainless Interior Construction and Contact Parts, 304 Stainless Exterior Construction, Insulated Tank, Last Running Food Ingredient Products, Dish bottom. Dome Top, Top Mount 5 HP Agitator with Gearbox and Eurodrive, Stainless Bridge for Agitator, Side Scrape and Bottom Sweep Agitation, Heavy Duty, Dual CIP Spray Balls, Stainless Alcove Front, Stainless Lifting Rings on Top, 20″ Side Manway Entrance, 3″ Center Discharge with 90 degree discharge, 24″ Stainless Legs, Temperature Probe Port, Thermowell Couple Port, Drawing available, Electrical 230/460 Volt / 60 HZ / 3 Phase, Overall dimensions 102″ L x 100″ Wide x 14′ High. This Process Mixing Tank was recently removed from a major food production facility operation and is available to be placed back into production immediately. Please reach out to us to discuss all of your process packaging and production needs. We have production ready equipment that is immediately available to go to work for you.