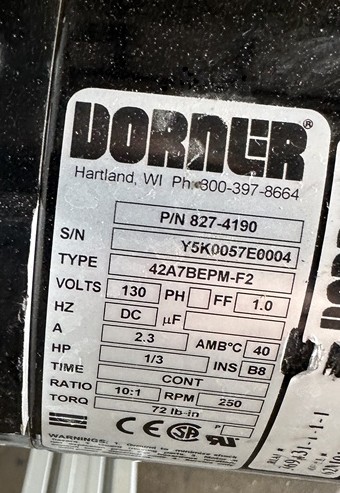

USED Dorner 20″ x 60″ Long Case Product Conveyor, Aluminum Frame Construction, Variable Speed Controls, 20″ Belting, 30″ Adjustable Elevation, Side Rails, Floor Levelers, 1/3 HP DC Drive, Electrical: 115 Volt / 50/60 HZ / 1 Phase, Overall Dimensions: 62″ Long x 24″ Wide x 35″ High. This Case Product Conveyor was recently removed from production. The conveyor has been function tested under power at our facility and can immediately be implemented back into production. Please contact us to schedule an onsite or video inspection of this item at our Used Packaging Equipment LLC Warehouse facilities located in Caddo Mills, TX. 75135. Call us today to discuss your Conveying, Filling, Capping, Labeling, Packaging, Production and Bottling Equipment needs.

A food product case product conveyor is a mechanical handling system designed to efficiently transport both individual food items and their packed cases (cartons, boxes, or totes) through various stages of manufacturing, processing, and packaging. First thing to note is that a used food or case product conveyor can minimize expense on the overall purchase for your production facility. By purchasing quality used bottle conveyor, food conveyors and case product transport conveyors from a company by the name of Used Packaging Equipment LLC located in Caddo Mills, TX. 75135. They are the best in the industry and have a huge selection in stock and ready to ship. Additionally, they typically function test their conveyors and used packaging machinery prior to shipment. This helps ensure the functionality of the machine along with quick integration and assertion into ones production facility. Whether large or small, the people at Used Packaging Equipment LLC can handle all of your conveyor and packaging equipment and machinery requirements and needs. These systems are essential for automating production lines, minimizing manual handling, and ensuring consistent product flow while adhering to strict food safety and hygiene standards. Key Characteristics and Functions: Hygiene and Compliance: Conveyors in the food industry are constructed with food-grade materials, such as stainless steel and specific types of plastic/silicone belting, that are easy to clean and resist corrosion. They must often comply with regulations set by bodies like the FDA to prevent contamination. Versatility: They are used to move a wide variety of products, ranging from raw ingredients like fruits, vegetables, and meats, to semi-finished goods and finished, packaged items. Efficiency: By automating the movement of products and cases, these conveyors significantly increase throughput, lower labor costs, and improve overall operational efficiency. Integration: They are often integrated with other processing and packaging machinery, such as sorting stations, washing lines, metal detectors, weighing scales, case packers, and palletizers. Common Applications are Food product, case product conveyors are utilized in numerous applications across the food supply chain: Processing: Moving raw ingredients through washing, sorting, cutting, cooking, or freezing stages. Packaging: Transporting products to filling, labeling, capping, and sealing machines. Case Handling: Moving empty cases into position for filling, then transporting filled, sealed cases to palletizing areas or distribution centers. Accumulation and Cooling: Holding products temporarily or moving them through cooling tunnels while maintaining quality. Inspection and Sorting: Facilitating manual or automated inspection processes by providing a steady flow of products or cases. Types of Conveyors; Various types of conveyor systems are employed, depending on the product and application: Belt Conveyors: The most common type for a wide range of loose and packaged food products due to their smooth, continuous, and easy-to-clean surface. Roller Conveyors: Often used for transporting heavier or bulkier items like crates, boxes, cartons, and pallets. Wire Mesh Conveyors: Ideal for applications involving high temperatures (ovens) or wet conditions (washing), as they are durable and allow liquids to drain. Vibratory Conveyors: Used to gently settle products into packaging or to separate and single-file items. In essence, a food product case product conveyor is the backbone of modern food manufacturing, ensuring that products move safely and efficiently from the raw stage to the final packaged case ready for distribution.

Description

USED Dorner 20″ x 60″ Long Case Product Conveyor, Aluminum Frame Construction, Variable Speed Controls, 20″ Belting, 30″ Adjustable Elevation, Side Rails, Floor Levelers, 1/3 HP DC Drive, Electrical: 115 Volt / 50/60 HZ / 1 Phase, Overall Dimensions: 62″ Long x 24″ Wide x 35″ High. This Case Product Conveyor was recently removed from production. The conveyor has been function tested under power at our facility and can immediately be implemented back into production. Please contact us to schedule an onsite or video inspection of this item at our Used Packaging Equipment LLC Warehouse facilities located in Caddo Mills, TX. 75135. Call us today to discuss your Conveying, Filling, Capping, Labeling, Packaging, Production and Bottling Equipment needs.