Description

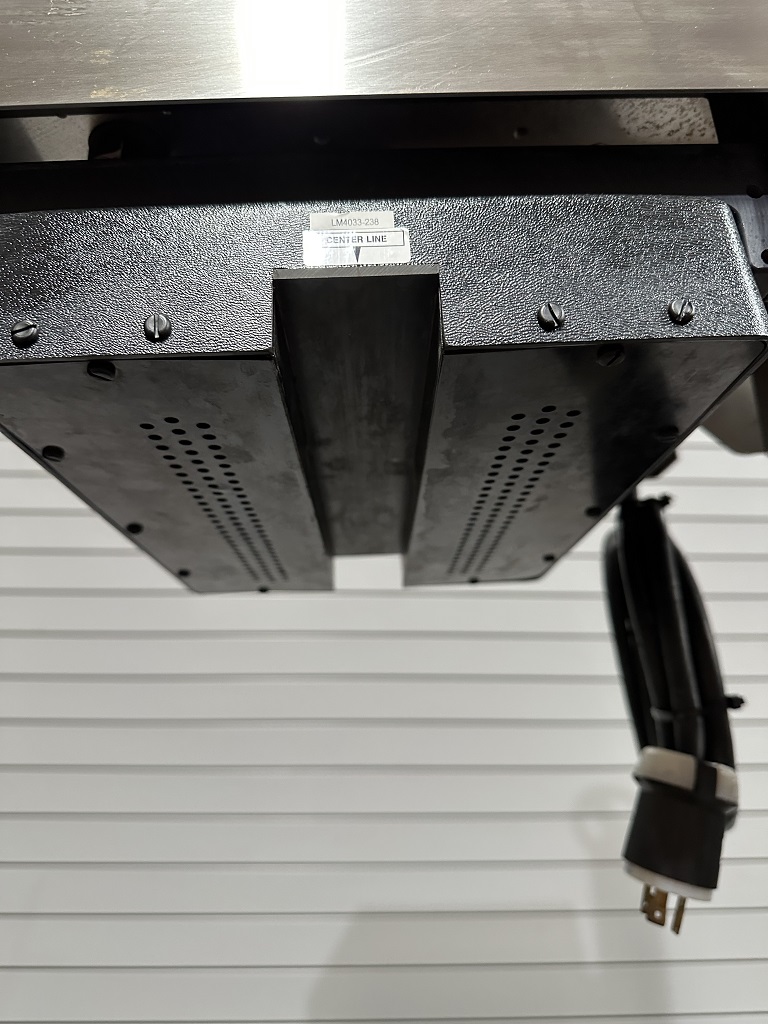

USED Enercon Air Cooled SUPERSEAL 100 Induction Sealer, Series SUPERSEAL 100, Model #LM5022-216, Serial #116222-1-1, 2014 Year of MFG, Air Cooled, Seal Head up to 38 mm cap sizes, Last Running 38 mm Closures, Status Indicators, Stainless Adjustable Base Stand, Casters and Floor Levelers, Operator Interface Controls, Electrical 240 Volt / 50/60 Hz / 1 Phase / 10 AMPS, Overall Dimensions 24″ Long x 24″ Wide x 68″ H. This Enercon Induction Cap Sealer was professionally removed from a midsized juice bottling production facility. This was last running products that used standard 38 mm plastic screw closure. This machine has been function tested at our facility and is ready to be placed back into production immediately. This Enercon Induction Cap Sealer machine ships direct from our Used Packaging Equipment LLC Warehouse Facilities located in Caddo Mills, TX. 75135. Please reach out to us today to discuss all of your filling, capping, labeling, packaging, processing and production requirements.