Description

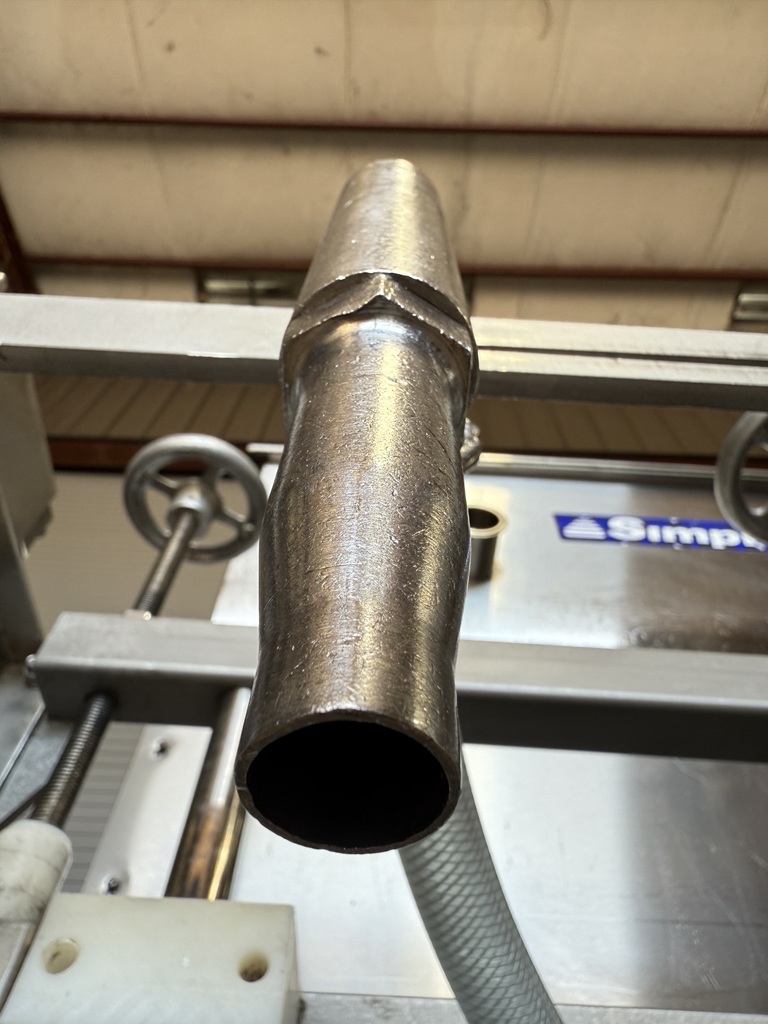

USED Simplex V-600 Automatic 6 Head Volumetric Inline Piston Filler, Model #V600, Serial #7676, Manufactured by Simplex – Napa, CA, 22 oz – 316 Stainless Pistons, Fill Range 3 oz. to 22 oz, Piston Size 1-7/8” dia. x 17” stroke, CAM Driven Pistons, 316 STAINLESS PISTONS, 5/8” Fill Nozzle Spout, Plunging Spout Assembly for BOTTOM UP Fill Process, 60 Gallon Stainless Product Balance Tank, Liquid Level Sensor, Pneumatic “Adjust-a-Fill” Feature, Stainless Frame Construction, Container Sensor, Adjustable Filling Valve Centers Up to 7”, Container Star-Wheel Indexing System, Variable Speed Controls, E-Stop(s), Stainless Floor Levelers, Casters, Air Regulator Assembly, Operator Interface Controls, ElectroCam PLUS5000 Controller, Electrical 230 Volt / 60 HZ. / 3 Phase, Overall Dimensions: 10′-4″ Long x 7′-6” Wide x 80” High. This unit was recently professionally removed from production in a food plant. Simplex volumetric piston fillers are extremely reliable and accurate piston filling machines. They can be used for a variety of products and application. Please reach out to us today for all of your bottling, filling and packaging needs.